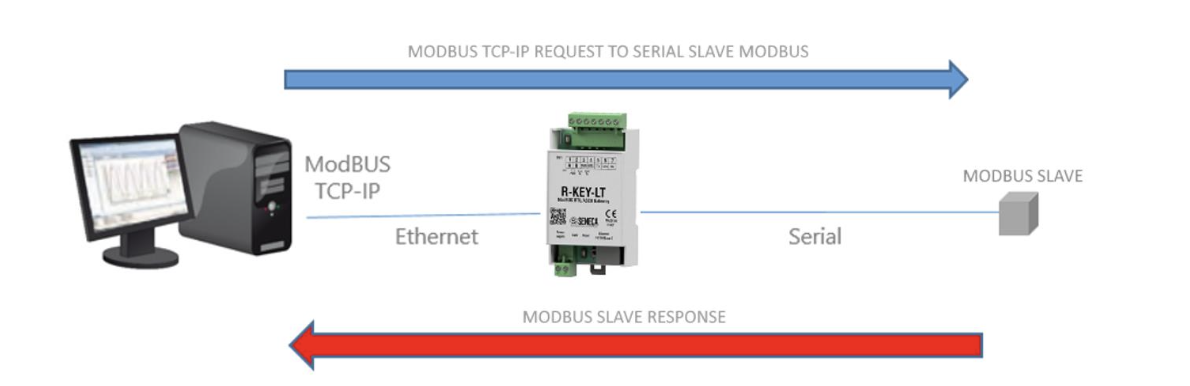

Modbus RTU to Modbus TCP/IP converter is considered the ultimate solution to solve the wiring problem in industrial signal transmission system. Modbus RTU signals will be connected together into IP address format or more precisely, the modbus RTU standard will be converted to Modbus TCP/IP on the ethernet line.

The R-Key-LT modbus signal converter opens a new era of industrial signal transmission. Modbus RTU signals will be converted to Modbus TCP-IP signals via RJ45 cables using internal Ethernet LAN networks. So what is special about the R-key-LT Modbus RTU to Modbus TCP/IP Converter? Let's find out.

Technical specifications of Seneca R-Key-LT modbus RTU to modbus TCP/IP converter

– Manufacturer: Seneca – Italy

– Model: R-KEY-LT

– Type: industrial gateway for Modbus RTU, ASCII, TCP-IP

– Conversion: Modbus RTU / ASCII to Modbus TCP / IP bidirectional

– Transmission method: RS485/ RS232 max 115K baud rate

– IT Protocols: Modbus RTU / ASCII / TCP / IP

– Connection: max 8 clients TCP-IP (server mode)

– Communication: max 10 modbus TCP Servers

– Working temperature -20…+70oC

– Mounted on DIN RAIL

– Install directly on the internal LAN by entering the default IP that comes with the device

– Isolate power source, input, output

– Connection port: RS232 / RS485 and 1 RJ45 port

– Power supply: 24Vdc

– Rx, Tx, Ethernet link indicator lights

– Plastic shell: ABS

– Dimensions: 32 x 110 x 52mm

Convert Modbus RTU signal to Modbus TCP/IP

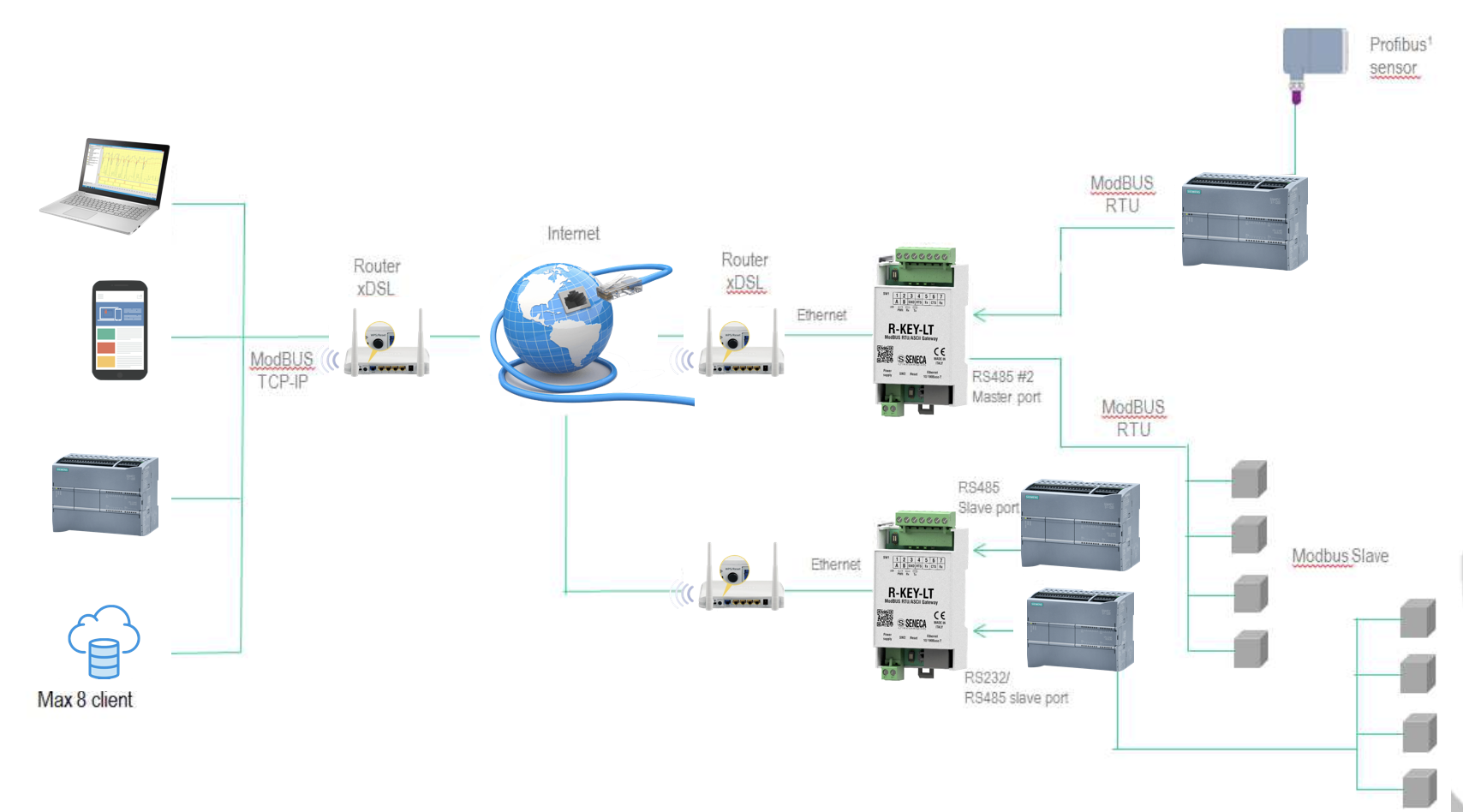

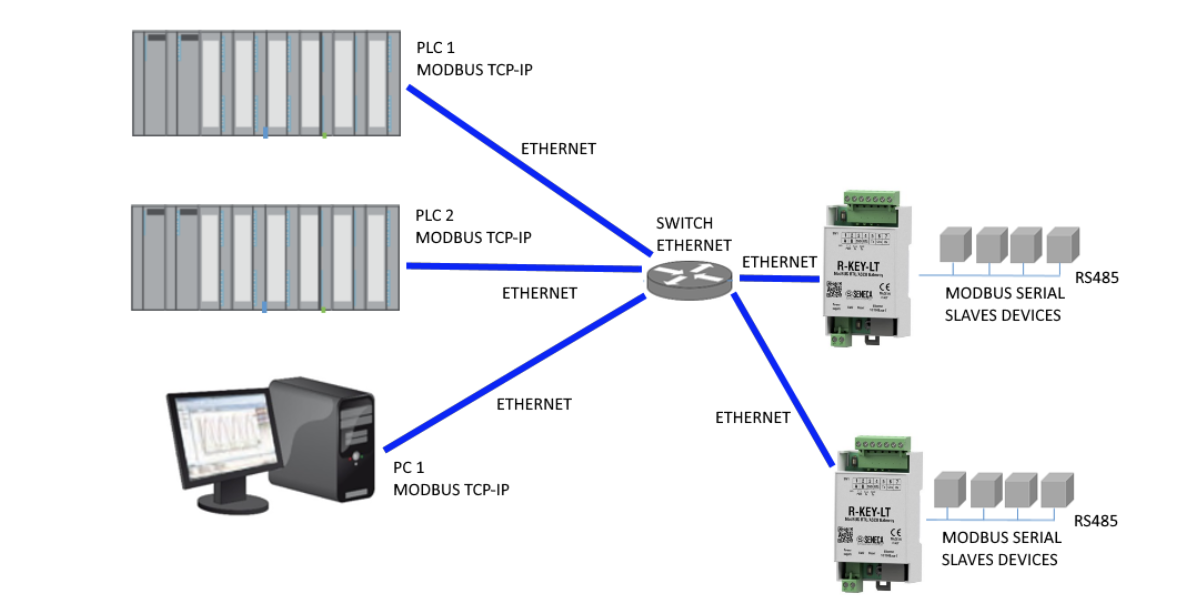

Modbus RTU to Modbus TCP/IP Converter Model R-KEY-LT is one of the most used converters when connecting to PLC. All devices with Modbus RTU slave signals enter R-KEY-LT via RS485. The ethernet port will be connected to the LAN via RJ45 port.

From here, all PLCs in the LAN can easily connect to the devices below the R-KEY-LT. This means that if you have many different PLCs that want to read the data below together, you can simply connect to the factory network to easily read the measuring and control devices.

For sensors with 4-20mA Digital or Analog output signals, we will combine them with a modbus converter to convert from Digital or Analog to Modbus. Then these devices will connect to R-KEY-LT to convert to Modbus RTU signals. Thus, with just a few devices, we can easily transmit data to PLC via Ethernet.

Convert Modbus TCP-IP signal to Modbus RTU

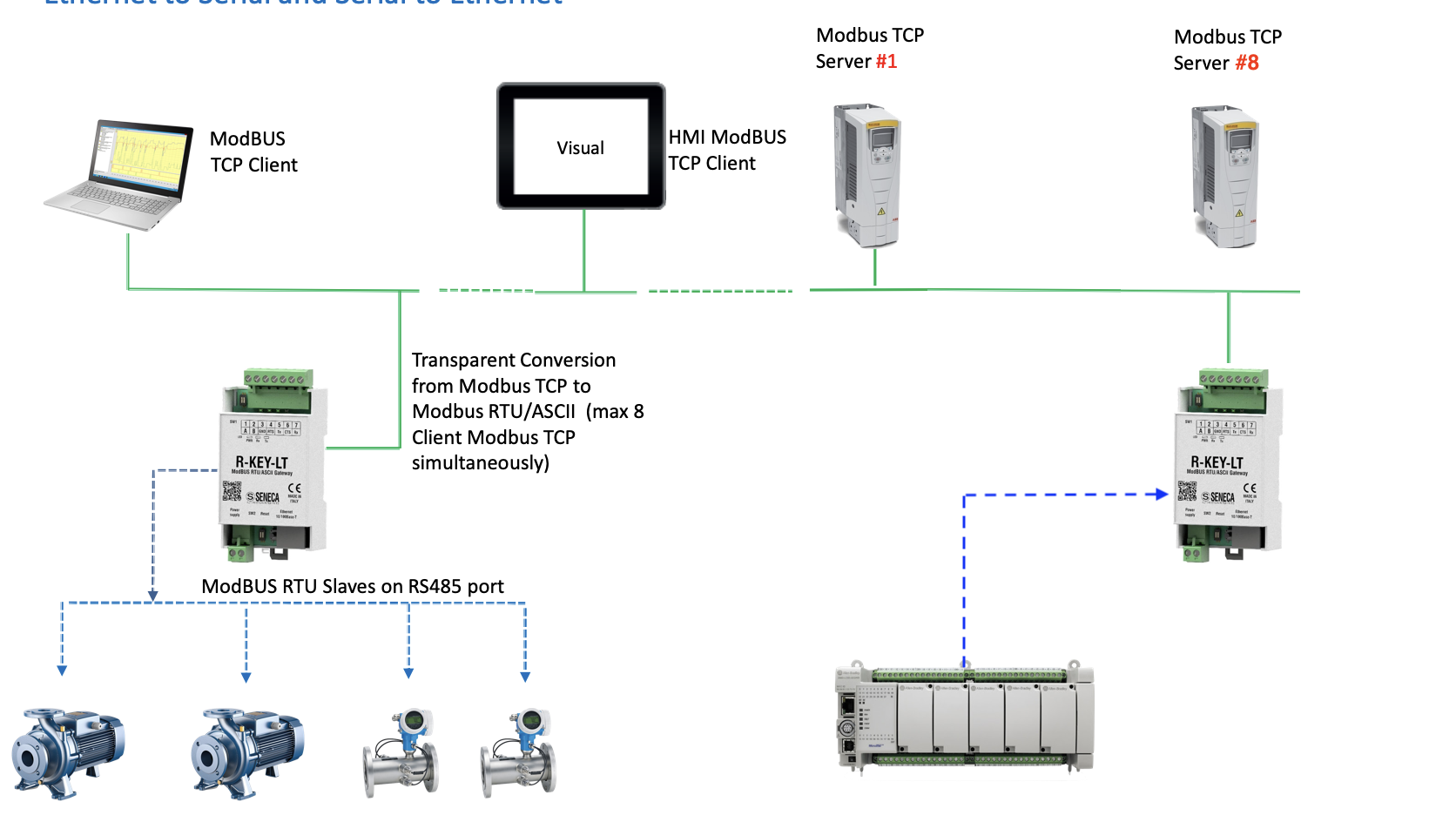

R-KEY-LT not only converts modbus RTU to Modbus TCP-IP but also can do the reverse. Converting modbus TCP-IP to modbus RTU is easy when PLC transmits signals via Ethernet but control devices can only communicate via modbus RTU.

Master devices can transmit control signals to control devices in parallel & independently when receiving requests from the control room. This means that you can control at the central room or you can also control remotely through independent HMI screens.

In case you have many different, independent servers that want to connect to many PLCs, displays and controls. R-key-LT does a good job of multitasking by being able to connect 8 independent clients and transmit to Modbus RTU slave.

Why R-KEY-LT is indispensable in PLC programming

The question is, without the R-KEY-LT industrial gateway, will the PLC system work well?

– The answer is yes. So why do we have to spend more money to buy the R-KEY-LT gateway?

– The answer is that it not only helps reduce connection cables to reduce costs but also makes it convenient to access data and transmit data anywhere.

One R-KEY-LT device connects all devices to the PLC

With only 1 R-KEY-LT gateway, 8 modbus slaves can be connected in parallel. In each modbus slave, there can be up to 128 modbus RTUs, equivalent to 128 independently addressable devices. With a device like Seneca's Z-8AI, there will be 8 analog inputs. Thus, with only one R-KEY-LT device, it can receive up to 8192 analog/digital signals below it.

A huge number, right?

Of course, connecting all to a gateway will cause the system to delay, so the response time may not be as fast as desired. That's why R-KEY-LT has an additional function, which is to be able to connect in series or parallel to increase response time. Isn't that great?

R-KEY-LT one device two features

The reason I say R-KEY-LT is a feature device is because it can transmit from Modbus RTU to Modbus TCP and vice versa, it can transmit from modbus TCP-IP to modbus RTU easily with just the DIP switch right on the device.

This allows us to use R-KEY-LT to transmit data to the PLC and also use another R-KEY-LT in parallel to transmit control commands from the PLC to the actuator.

I have never seen a device that is as compact and multifunctional as the R-KEY-LT. Perhaps that is why it is an indispensable device in modern electrical cabinets today.

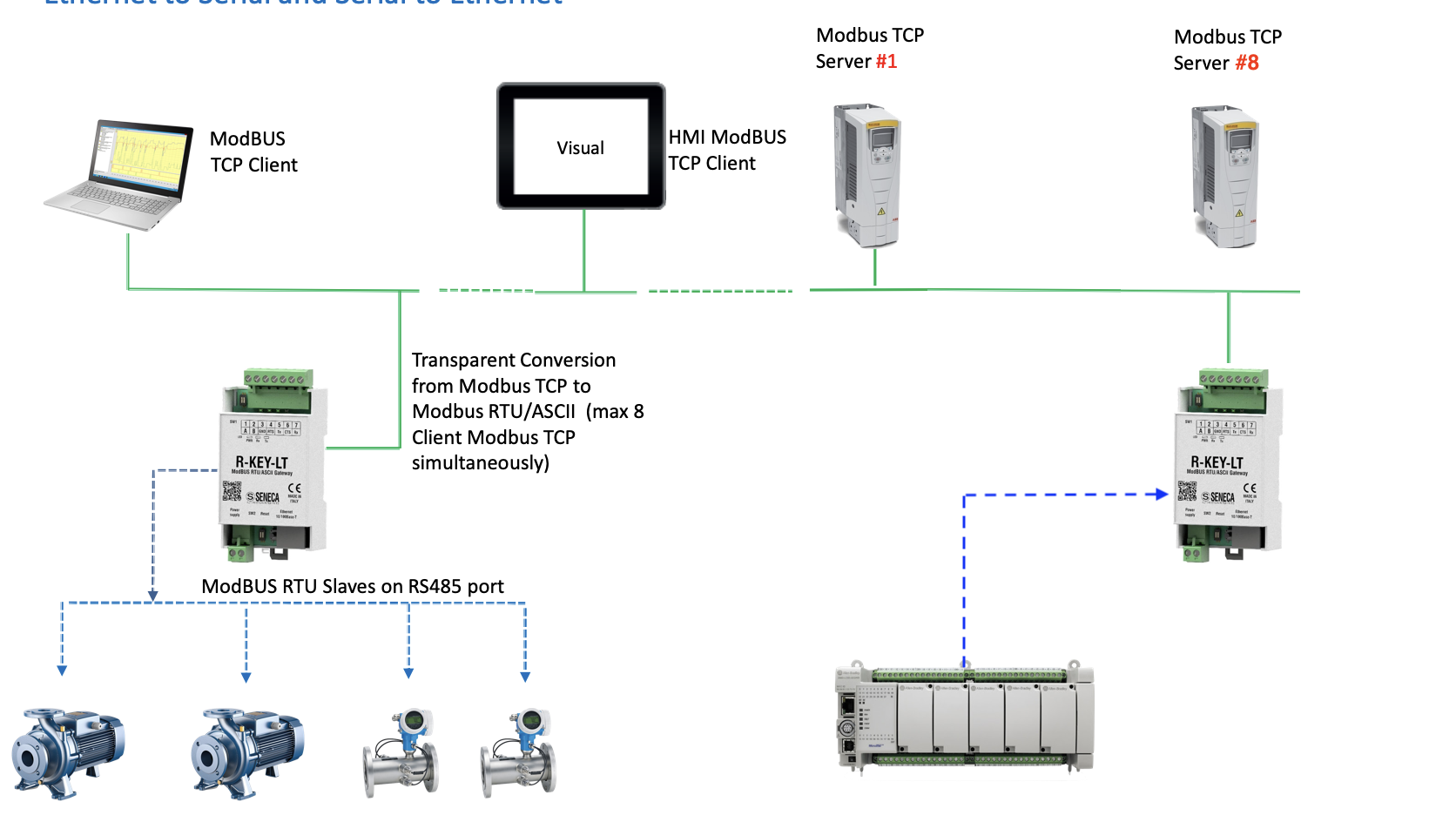

Access anywhere with just Ethernet\

With an Ethernet port directly connected to the network hub, the R-KEY-LT can create its own separate IP port. PLCs or devices with integrated Modbus TCP-IP standard can access this IP address to easily retrieve data from the R-KEY-LT.

By using each R-KEY-LT as an IP address, we can connect many R-KEY-LTs at many different locations to the same network system. Computers and PLCs at many different locations can access each location of R-KEY-LT simply by accessing the correct IP address, address, and Baud.

Where to buy modbus RTU to Modbus TCP:IP converter

Seneca R-KEY-LT modbus RTU to modbus TCP:IP converter is manufactured in Italy and officially distributed in Vietnam by Hung Phat company. We are the sole representative of Seneca in Vietnam with signal conversion and communication equipment in industry.

With the growing demand for Model R-KEY-LT, we always have a large number of this industrial gateway available at Hung Phat. If you need more information about Gateway R-KEY-LT, do not hesitate to contact us.